Buckman Laboratories International

Manufacturing

increase velocity, spark innovation

An International Manufacturing company hired KEYSYS to create an application to automate the measurement & reporting of the blade wear in their tissue manufacturing process

CLIENT:

Buckman Laboratories International is a specialty chemical company that is globally renown in over 90 countries across the globe. Buckman specializes in pulp, paper, leather, water treatment, and process chemistry.

PROBLEM:

Buckman Laboratories International, Inc desired to automate the measurement process for creping blades.

For tissue paper products, the process of creping is what gives the sheet the required lower density and increased caliper. The creping process, more than any other step in tissue making chain, is what determines the final product’s characteristics.

When tissue paper is sent through a dryer, Buckman’s 40-foot creping blades ride the drum of the dryer and scrape the tissue paper off of the dryer. A creping blade is typically replaced at least once a day due to the intensity of the wear from scraping the dryer.

Prior to KEYSYS’ engagement

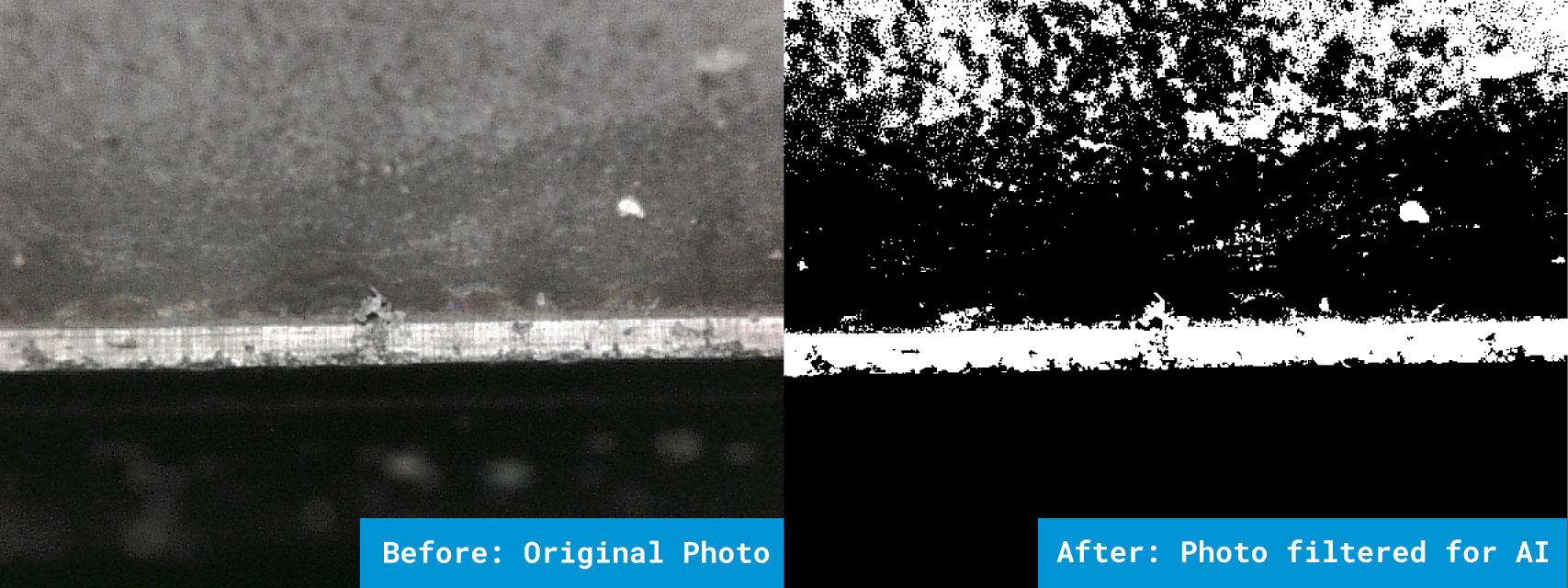

Inspecting the used blade consisted of Buckman manually using a microscope camera to measure the wear patterns of the 40-foot blade, which was only millimeters wide. Depending on the blade, there could be anywhere between 30 to 60 measurements. The measurements were then manually entered into spreadsheets to later create reports.

As a daily manual process, this procedure was:

- Cumbersome

- Time-consuming

- Error-prone

APPROACH:

Buckman engaged KEYSYS to streamline this manual measurement process.

KEYSYS created a standalone desktop application that automated the blade inspection process and inspection report generation.

KEYSYS wrote software that calibrated the camera/microscope to measure the blade edge, and calculate the wear rate in both imperial and metric units.

Additionally, KEYSYS created the application to generate reports including:

- Wear rate

- The angle of the wear

- Length of time the blade was in service

OUTCOME:

The platform replaced the use of spreadsheets and stored all information in PDF format making it easier to:

- Read

- Access

- Export reports

IMPACT:

Through the desktop application,

KEYSYS automated around 95% of the measurement and reporting process.

This saved Buckman Laboratories International considerable time and overhead cost.

LEE DANIEL

Chief Technology Officer

SPECIALTIES

- Cost Optimization

- System Integration

- Serverless Architecture